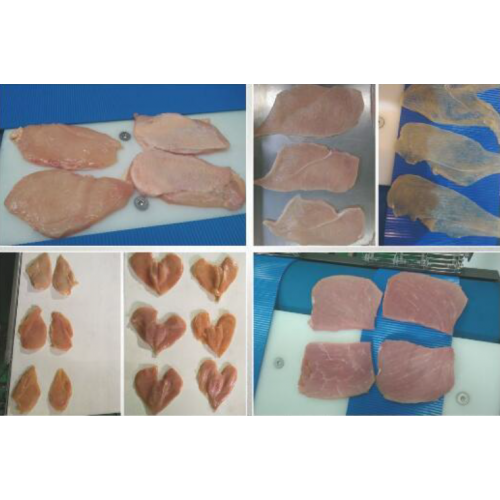

How to: Explanation of the Horizontal Chicken Breast Slicing cutting system

Multiple slices with Horizontal cutting also capable of butterflying.

Suitable for fresh pork, beef, lamb and poultry

- High cutting precision, multiple slices in single cut with minimum thickness of 3mm, maximum thickness of 50mm.

- Through blade cassette changing, switch between chicken breast slicing function and butterflying function as well as cutting thickness adjustment is easily and quickly completed.

- Floating upper belt, wide application for different precut thickness.

- Multilayer cutting of different thickness.

- Double feeding operation, high yield, 120 pieces/min.

- Quality module type mesh belt, long life guaranteed.

- SIEMENS electrical parts, CE approved safety service.

- Made in stainless steel and engineering plastic, easy to clean and HACCP standard.

- Easy operation and low maintenance cost.

Technical Parameters

| Belt Width | 2 x 156 mm |

| Belt Speed | 3~15m/min |

| Cutting Speed | 120 pcs/min (Dual Lane) |

| Max Product width Input | 140 mm |

| Max Product Height Input/Output | Based on Height of Guiding Bar + 5mm of product height |

| Minimum Cutting Thickness | 3 mm |

| Maximum Cutting Thickness | Depends on metal guide combination (see brochure) |

| Power | 440V - 60Hz - 3PH / 220V 60Hz 3PH |

| Overall Dimension | 1780 x 1150 x 1430 mm |

|

Metal Guide Combination Chart Number of horizontal multilayer blades are based on height of guiding bar. Tip: Product should always be 5mm higher than guiding bar. |

|||

|

Height of Guiding bar |

3mm Metal guide |

4mm Metal Guide |

5mm Metal Guide |

|

20mm |

No. of blades - 6 |

No. of blades - 5 |

No. of blades - 4 |

|

25mm |

No. of blades - 8 |

No. of blades - 6 |

No. of blades - 5 |

No comments:

Post a Comment