Ruhle High Tech Tumbler MPR 900

Two independent arms, a feed system and a 900 Lt container can process approximately 630 kg of product efficiently, fast and with incredible consistency. In addition, cooling, vacuum treatment and variable arm speeds ensure optimum operating results. The secret of this success lies in its control technology, reflecting decades of experience. The container can be tilted in different positions. The large diameter container enables good rolling of the meat. The variable range of the rotational speeds from 1-25 rpm allows endless variation for each arm. The two arm system provide air packet free, uniform and very gentle processing of the meat.

Technical Specifications:

| Machine height | 2.350 - 3.250 mm |

| Machine length | 2.200 mm |

| Machine width | 3.100 mm |

| Machine weight | 2.000 kg |

| Connected load | 400 V, 16,1 kW, 32 A |

| Filling capacity | 675 l |

| Container size | 900 l |

| Coolant | R 404 |

| Variable arm drive | 0 - 25 U/min |

| High-vacuum system | 0 - 95 % |

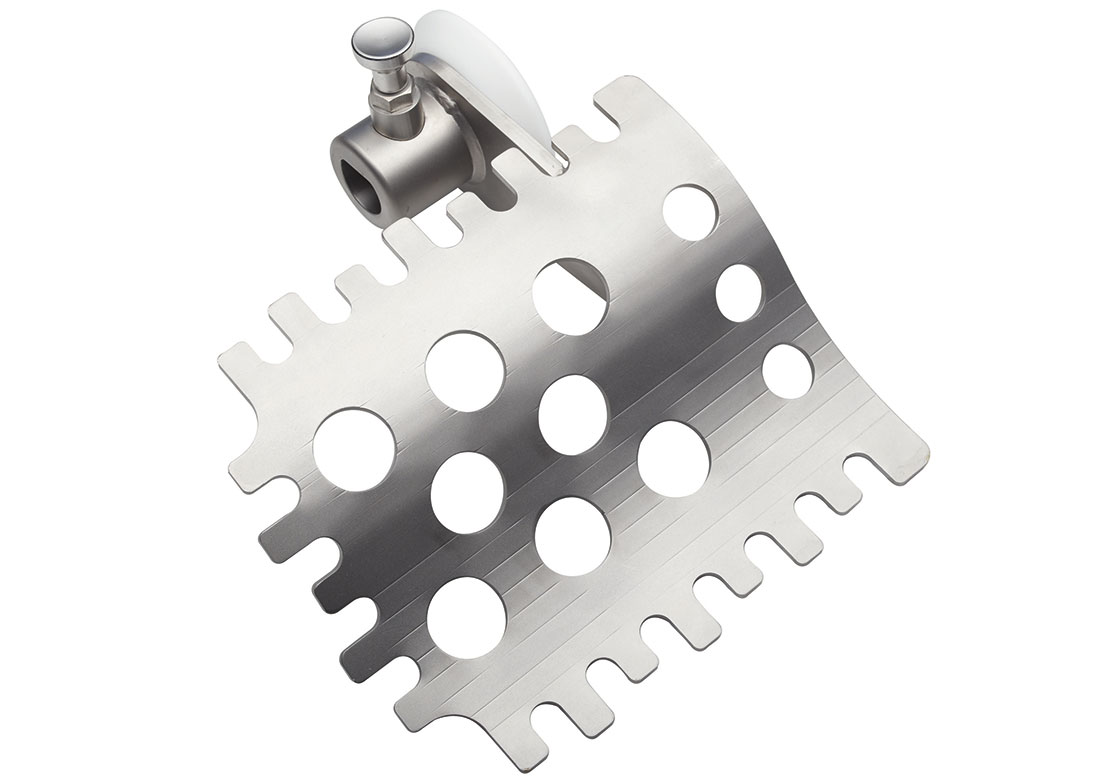

Efficient Scraper

The shape of th emixing arm is designed for handling and processing delicate products. A rotating scraper keeps the container surface perfectly clean. Nothing is left unprocessed, it all stays in the mixture.

Adjustable Vacuum System

Vacuum can be achieved rapidly and slowly depending on the product. User can select a precise setting within the control range between 0-95% vacuum. A supply pipe installed directly into the containers cooling jacket ensures that only chilled air enters the drum. As a result frequent aeration has no effect on the containers temperature.

Precise Temperature Control

The powerfull cooling unit inserts the coolant directly into the perfectly insulated container. This enables very fast temperature regulation and precise adaptation to all temperature requirement. Optionally the cooling unit can also be run as a pump an supply heat up to 80° C.

Integrated Feed System

Automatic push button positioning of the container and container lid enables integrated feeding with a 200 ltr standard trolley. Filling only takes a few seconds and emptying less than a minute. Varying the angle of the drum during the running of the program grantees the optimum results.

Networked tablet PC control

The original MPR 900 can be controlled by any tablet or smartphone. Receipes can be created intuitively and everyday tasks can be easily facilitated by a smaller control interface.Your own date can be stored safely using cloud software which like the control app can be reloaded at any time.

Equipment:

- Touch-PC control

- 100% container insulation

- Motorized lid

- Container swiveling

- Direct cooling system

- Stainless steel air canal, cooled

- Feed system

- Counter-rotating mixing arm

- Quick arm fastening

- Scraper click assembly

- CE / GS certificate of inspection

Accessories:

Double Scarper Arm Mixing Arm

|  | ||

Fine Food Mixing Arm Scraper Arm

No comments:

Post a Comment