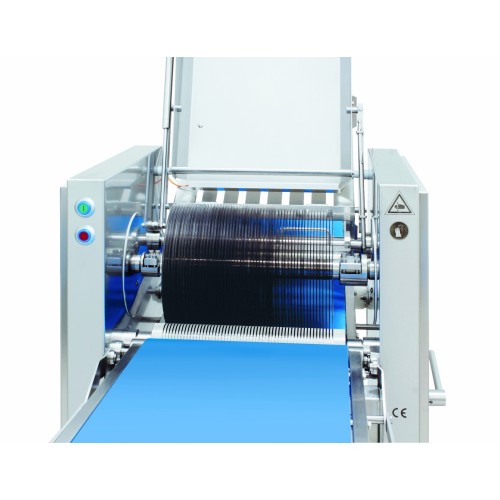

Nock NRE 800 Scale Ice Maker

Scale Ice Maker with daily performance of 800 kg scale ice

Features

- scale ice maker with a daily performance of approx. 800 kg scale ice in 24 hours

- machine complete with evaporator and refrigeration aggregate

- horizontal rotating evaporator

- separation of aggregate from evaporator and tank by construction

- thus very easy daily cleaning and disinfection with high pressure and foam as with other food processing machines, without demounting the stainless-steel water tank

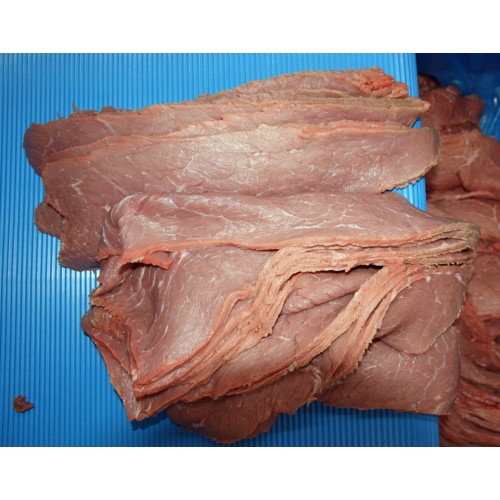

- ice temperature approx. minus 8°C

- thickness of the scales approx. 2 mm

- stainless-steel casing

Standard equipment

- complete machine with integrated, air-cooled refrigeration aggregate (Bitzer)

- refrigerant R449A

- stainless-steel casing

Options

- underframe

- version without aggregate (type NRE / SK)

| Technical data NRE 800 | |

|---|---|

| ice output | approx. 800 kg scale ice / 24 hours (at +25°C ambient temperature and +15°C water temperature) |

| refrigeration | air |

| refrigerant | R449A |

| permitted ambient temperature | +6°C < t < +38°C |

| dimension W x H x D (without optional under frame) | 1100 x 1400 x 1000 mm |

| weight | 320 kg |

| water connection | ¾“ external thread, min. 0.5 bar |

| electric connection | 3 AC - 400 V - 50 Hz other voltages upon request |

| electrical performance | 4.1 kW |