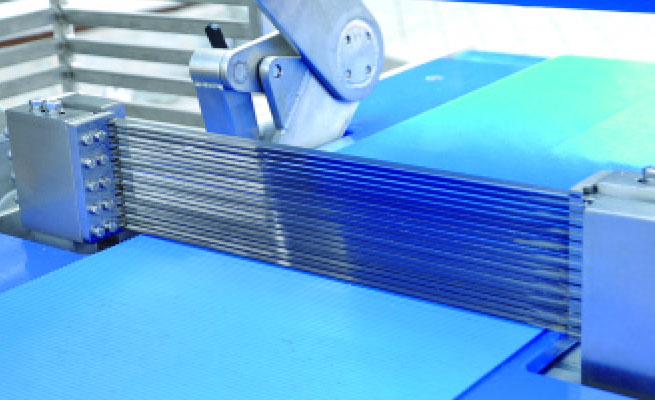

Tough Red Meat or Vegetable Horizontal Slicer

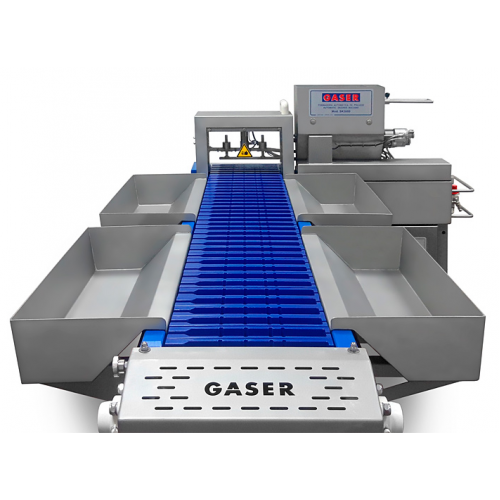

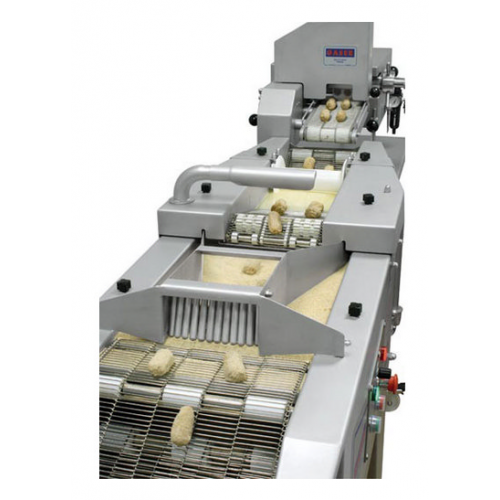

This machine adopts a new double floating belt conveying design, widely cutting a range of (380mm width × 120mm height).

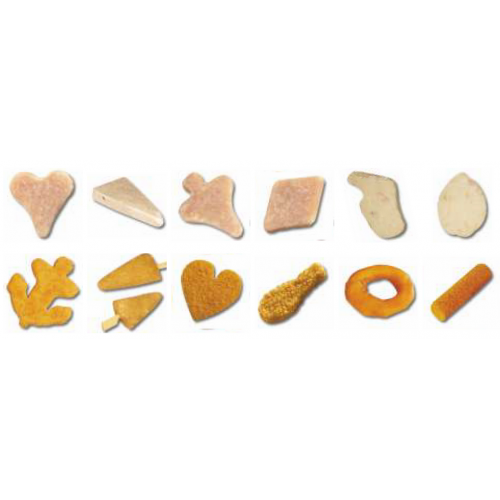

It can meet customers’ requirements for processing different sizes and various shapes of raw materials.

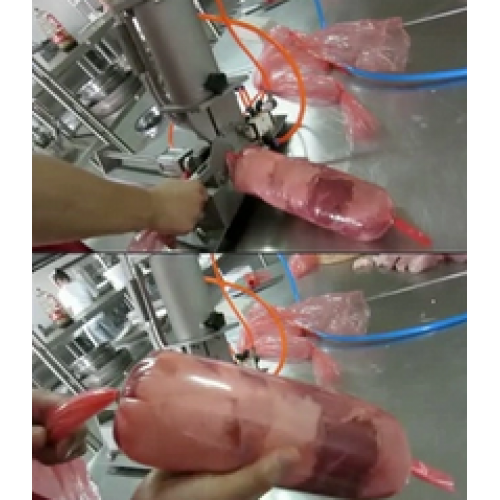

Suitable for fresh boneless meat such as beef, lamb, pork, chicken, seafood, and cooked products.

It can be also used for sliced products such as block shape vegetables.

Horizontal conveyor style can combine with other equipment to achieve a continuous production line.

Features:

- Suitable for tough products with tendons or cartilage, or vegetables.

- Safety switch equipped on the cover.

- Stainless steel and non-metallic materials in conformity with FDA standard.

- Pneumatically lifting is adopted for compacting the conveyor belt. Easy operation and convenient maintenance.

- Adjustable cutting thickness; High efficiency and cutting accuracy.

- The conveyor belt is driven by drum motor which is safe, reliable and easy to clean

Technical Data:

| Raw material temperature: | ≥-2℃ |

| Production capacity: | 1000kg/h |

| Belt width: | 380mm |

| Belt speed: | 3-15m/min(adjustable) |

| Cutting thickness: | ≥4mm |

| Input height: | 1000±50mm |

| Output height: | 1000±50mm |

| Power: | 480V/220V 60hz 3ph |

| Overall dimension: | 2180×1155×1480mm |

|

Special multi-blades structure design can realize all the blades to achieve best slicing satiation and minimize the slicing error. |

|

Pneumatically double-floating compaction conveying system is adopted, which can be adjusted automatically according to different thickness |

|

The pneumatic system adopts the German Festo brand, which is safe and reliable |

|

Easy-to-disassemble belts, ensuring comprehensive cleaning, CE approved. |

-500x500.png)