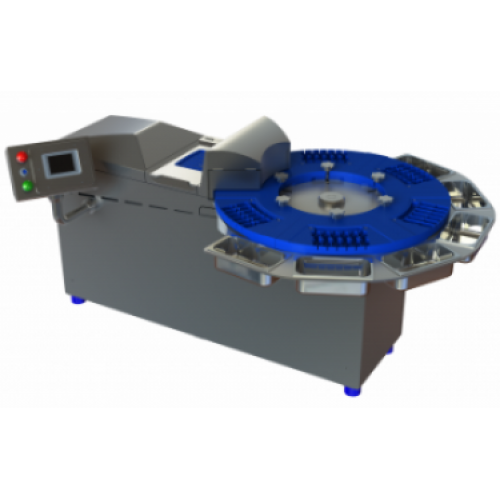

Fully-Automatic Skewer Machine

This machine is composed of a rotating plate on which it is placed on 6 removable molds with 4 to 6 shapes. Ingredients that be used include meat, fish, vegetables, fruits, and other processed products. The ingredients are prepared, potentially cut, and then manually positioned in a tailored shape.

With each rotation of 60 ° of the tray, the machine engages with the

skewers mold while the operators fill the others. The shape study is

personalized, meaning it is specific to your product/machine. The

interchangeability of the trays allows for an instant and fast change of

production without cleaning the machine.

Specifications:

- Kebabs made are identical to the handmade kebabs.

- The kebab’s handle is not stained by marinades, thanks to an automatic horizontal skewering.

- Can be easily disassembled when needing to be cleaned.

- High speed to change molds without tools which allows to switch from one type of kebab or marinade to another very quickly.

- Large configuration diversity: Gunshaped skewers only, and automatic or manual selection.

- The machine is easy to clean and considers the constraints of the food industry.

- A touch screen makes the communication easier between the operator and the machine.

- The touch screen display includes a self-diagnostic system.

- Adjustable speed.

- One cycle corresponds to the passage of one mold in front of the skewering unit that allows simultaneous production of 4 to 6 kebabs.

- The quantity of shapes / mold depends on the size and complexity of the kebab to produce.

Technical Data:

- Maximum production rate of the machine: 800 cycles/hour.

- Power: electrical control and pneumatic power

- Materials: stainless steel and polymers

- Necessary Pressure: 6 Bar or about 90 PSI

- Air Consumption:15 m³/h (700 cubic foot/hour) under 6 bar of pressure (90 PSI)

- Electricity: 220V/1Ph

- Air Quality: for a good running of the machine, we recommend using an air dryer.

- Due point: between +2° and +3° (5.5 to 6 kg of water / m³ of air)

The machine is delivered with 6 molds that has been built according to the client’s product.

- The client can send pieces of meat, or pictures with the dimensions and all the features of the product and skewer. Then a “testing mold” (very small mold) is made in which you could produce one kebab to see if everything is OK.

- If the client confirms the testing mold, the mass production for the 6 big molds will be done.

No comments:

Post a Comment