Scope of Application

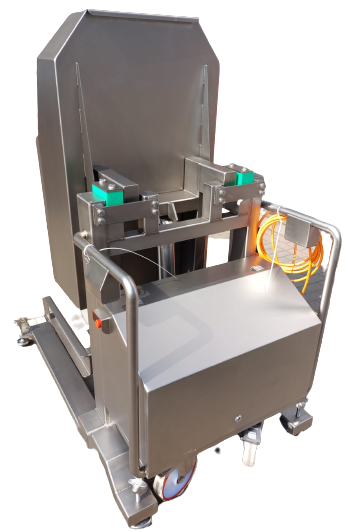

This is mainly used for detecting the metal chips inside any products

such as poultry, seafood, ice-cream, frozen food, sugar, tea,

pharmaceutical, health care products, etc.

Technical features:

1.Adopted DSP advanced technology (DSP Chip)

2.Record data 52 kinds of different products

3.Program new products and save data in system

4.Phase tracking function restricts the product effect and read high stable detection sensitivity

5.Digital lcd screen operation

6.Strong recommended for seafood, meat, salt, and other high-effect products

Technical specifications:

Tunnel size: (above belt) based on chart A-F

Basic sensitivity (not loaded products): Based on chart selection A-F

Conveyor length standard 1,500mm, belt width 360mm

Conveyor height above ground to belt standard 750mm + - foot cup 100mm with moveable wheels

Rejection system: Audible with red light warning alarm, belt stopped automatically.

Belt speed: 25 meters/min fixed or optional variable speed.

Flow direction: from Right to Left (facing the operation panel) or opposite.

Materials: white PVC belt, tunnel housing 304 grade stainless steel, conveyor 201 grade stainless steel

Operation System and Panel Language: English

Spare parts: calibration metal test cards 1 set

Power supply: Voltage 220VAC, 60Hz, 1 Phase, American plug

PKG dimension: L1780 x W1100 x H1250 mm, 2.45CBM, G.W 320KG

Inspection tunnel size & Sensitivity ability chart:

| A | B | C | D | E | F | |

| Opening Width | 300 mm | 400 mm | 400 mm | 500 mm | 500 mm | 600 mm |

| Opening Height | 100 mm | 120 mm | 150 mm | 200 mm | 250 mm | 300 mm |

| Sensitivity of Ferrous | Φ0.8mm | Φ0.8mm | Φ1.0mm | Φ1.0mm | Φ1.2mm | Φ1.8mm |

| Sensitivity of Non- Ferrous | Φ1.0mm | Φ1.2mm | Φ1.5mm | Φ2.0mm | Φ2.0mm | Φ2.5mm |

| Sensitivity of SUS 304 | Φ1.8mm | Φ2.0mm | Φ2.0mm | Φ2.5mm | Φ2.5mm | Φ 3.0mm |

TIP: The closer the window is to actual product the better the sensitivity.