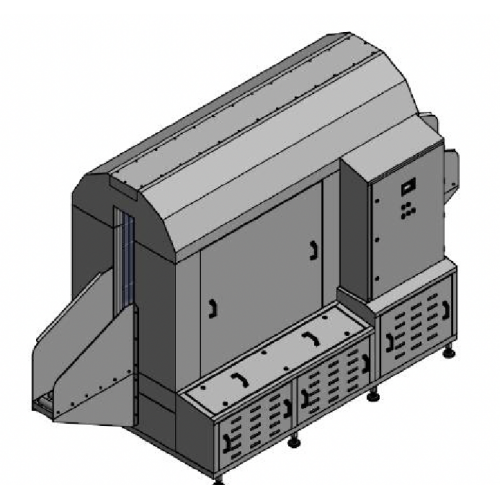

Pallet Washer 50-100

Compact conveying pallet washer machine for fast and effective cleaning of slight to moderately contaminated plastic pallets.

The pallet washer is divided into a main wash and a rinsing zone. In the main wash zone the pallets are cleaned with circulating water which is invariably kept at the desired temperature by the installed tank heater. The water of the main wash zone is constantly filtered by an elaborate filtration system. In the rinsing zone the pallets are rinsed with clean fresh water and subsequently conducted into the tank of the main wash zone to be re-used. This procedure achieves minimal water, energy and chemical consumption as well as superb wash results.

In order to ensure an optimal cleaning of all faces, the pallets are transported by a conveyor chain at even distances through the unit; the installed rotatable. Clip-eyelet flat nozzles ensure an efficient cleaning of the pallets.

Specifications

- Capacity: 50-100 pallets per hour

- Pallet transportation: Upright, horizontal

Technical data

Guiding plate IN + OUT:

- Length: 800mm

- Feature: with built-in roles

Main wash zone:

- Length: 1620mm

- Tank capacity: 450 liters

- Tank heating: 2 x 4kW

- Washing temperature: 40 - 65°C adjustable

- Nozzles: flat nozzles

Conveying system:

- Conveying system: transport chain

- Distance of carrier: 100mm

Heating system:

- System: electrical heater

- Power: 3 x 9kW

Utility connections:

- 400V / 50Hz (Other options upon request)

- Control voltage: 24V

- Water inlet: 3/4“, 1 - 10 bar, Cold- and warm water

- Water outlet: 2” ball valve

Options

- Drying module – Heating system with higher air blowers and uses electric energy

- Drying via centris - Pallet spinner to remove excess water with less energy consumption

- Water filtration

- Fume extraction exhaust system

- One-man operation

- With conveyor belts

- Dosing pump

*Can be customized according to customer requirements*

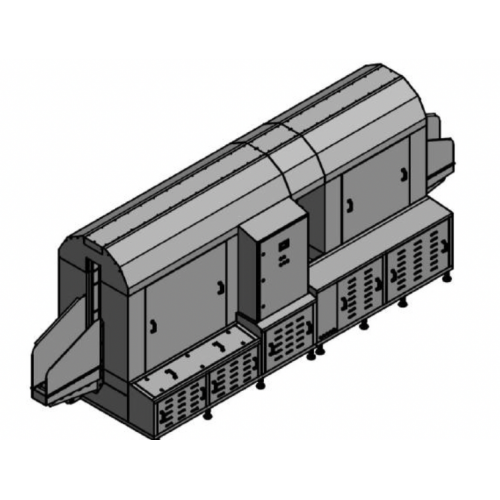

Pallet Washer 100-200

Compact conveying pallet washers for fast and effective cleaning of slight to moderately contaminated plastic pallets.

The unit is divided into a main wash, rinsing zone and drying zone. In the main wash zone the pallets are cleaned with circulating water which is invariably kept at the desired temperature by the installed tank heater. The water of the main wash zone is constantly filtered by an elaborate filtration system. In the rinsing zone the pallets are rinsed with clean fresh water and subsequently conducted into the tank of the main wash zone to be re-used. This procedure achieves minimal water, energy and chemical consumption as well as superb wash results. In the drying zone (Cold-air booster) the crates are air boosted with cold air.

In order to ensure an optimal cleaning of all faces, the pallets are transported by a conveyor chain at even distances through the unit; the installed rotatable. Clip-eyelet flat nozzles ensure an efficient cleaning of the pallets.

Specifications

- Capacity: 100-200 pallets per hour

- Pallet transportation: Upright, horizontal

Technical data

Guiding plate IN + OUT:

- Length: 800mm

- Feature: with built-in roles

Main wash zone:

- Length: 1620mm

- Tank capacity: 450 liters

- Tank heating: 2 x 4kW

- Washing temperature: 40 - 65°C adjustable

- Nozzles: Clip-eyelet (rotatable flat nozzles)

- Filter system: 2 pcs

Rinsing zone:

- Length: 780mm

- Temperature recommended: 60 - 85°C

- Nozzles: flat nozzles

Drying zone:

- Length: 1500mm

- Blower: 5,5kW

Conveying system:

- Conveying system: transport chain

- Distance of carrier: 100mm

Heating system:

- System: electrical heater

- Power: 3 x 9kW

Utility connections:

- 400V / 50Hz (Other options upon request)

- Control voltage: 24V

- Water inlet: 3/4“, 1 - 10 bar, Cold- and warm water

- Water outlet: 3” – 1 ½“ ball valve

Options

- Drying module – Heating system with higher air blowers and uses electric energy

- Drying via centris - Pallet spinner to remove excess water with less energy consumption

- Water filtration

- Fume extraction exhaust system

- One-man operation

- With conveyor belts

- Dosing pump

*Can be customized according to customer requirements*

No comments:

Post a Comment