Table Top Cheese Portioner

Ideal to cut manually hard and semi-hard cheeses. Due to its small dimensions and to its simple structure, the portioning machine Rock 18 adapts perfectly to any kind of counter (e.g. delicatessens, grocery stores, small retail outlets)

It allows to obtain in a semi-automatic way, portions of cheese of the desired weight. Its production capacity and tightly bound by the time it takes to prepare the form of grain to be cut.

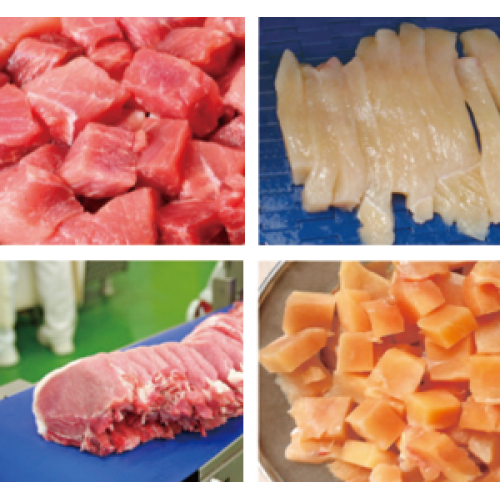

This can cut slices of any kind of hard cheese, such as Parmesan cheese and other aged cheese.

- Special blades (blade with holes) serves to cut hard cheeses like Parmesan, or Grana Padano or very seasoned Pecorino.

- Smooth blades: suitable for cutting hard and semi-hard cheeses. (smooth blade covered with food-grade Teflon)

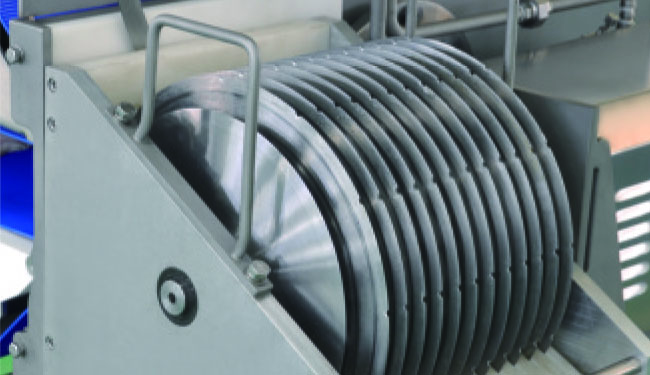

- Tool for cutting into portions in a pre-defined number in one single cut, easy to disassemble and interchangeable with cutting blade. (optional for Rock18 & Rock20)

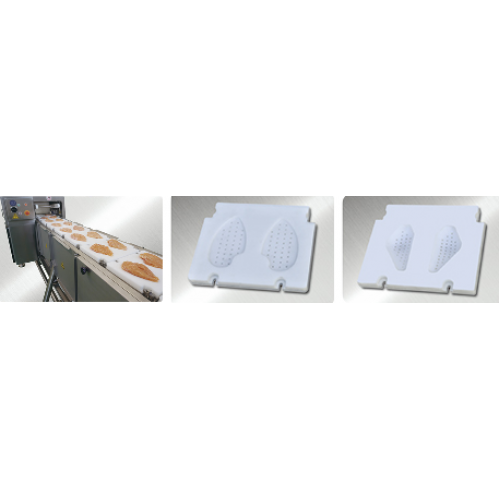

-500x500.jpg)

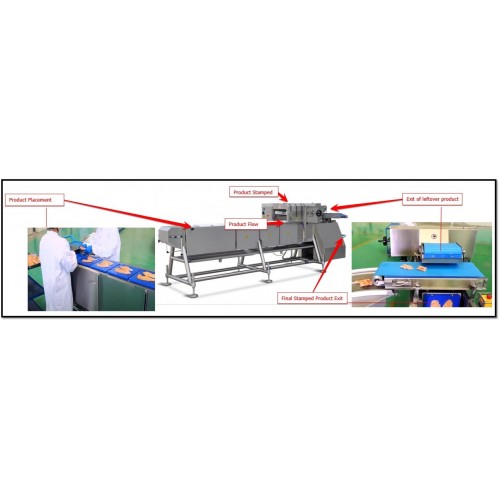

-500x500.png)

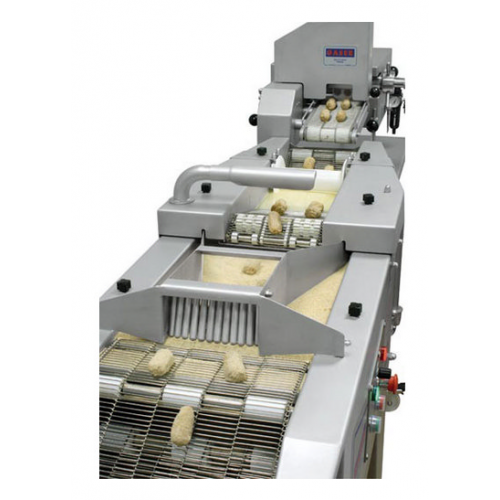

-500x500.png)