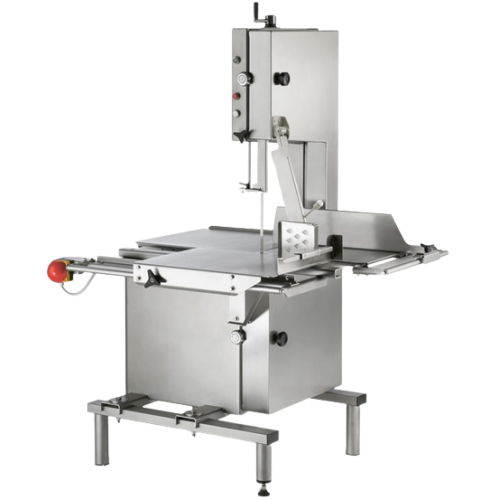

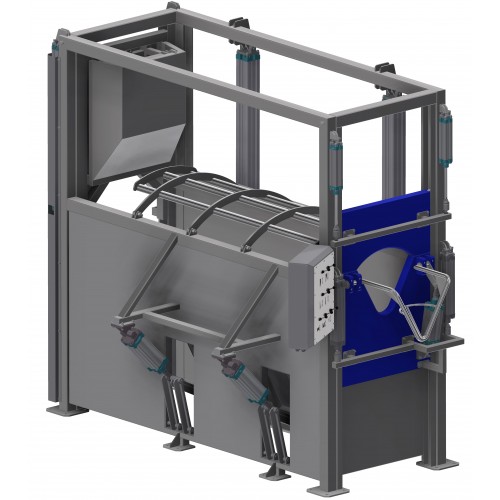

This machine is ideal for all type of bones, it is our Stage 1 primary starter in our Bone Crsuhing and grinding Process.

Stage 2 is our Bone Crusher Combi grinder machine.

This machine can pre-break large bones upto 431mm in length to output range of 30 -80 mm perfect for further processing for our Bone Crusher grinder for faster and most efficient production.

The pre-breaker can be customised to work with inclined conevyor system for transferring pre crushed bones automatically to our Bone Crusher grinder hopper.

Types of Bones:

- Fresh or frozen

- Beef Femur bone

- Sheep bone

- Fish bone

- Chicken bone

- Goat bone

- Donkey bone

- Deer bone

- Beaver bone

- Bison bone

- and more...

Specifications:

- Motor: 5.5kW

- Material of Knifes and Shaft: S440C Stainless Steel

- Hardness of Material: 53-54 HRC

- Material of cavity, silo and frame: SS304 stainless steel

- Material of Motor casing: SS304 Stainless Steel

- Material of Control cabinet: explosion proof and waterproof SS304 Stainless Steel

- Power: 220V 60Hz 3Ph (other powers available on request)

- Crusher blade thickness: 30mm

- Crusher blade type: 3 hooks

- Product output size range: 30 - 80mm

- Output capacity: 300-500 kg/hr. (660-1100 lbs.)

- Suitable for bone length of 431mm (16.9 inches)

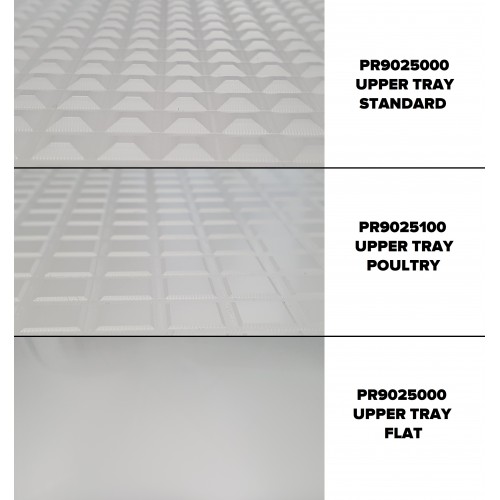

-500x500.png)

-500x500.png)

- Red Meat - Std.gif)

- Poultry.gif)