Bone Crusher Combi Grinder 400

Note: Video example is model Bone Crusher Combi Grinder 400

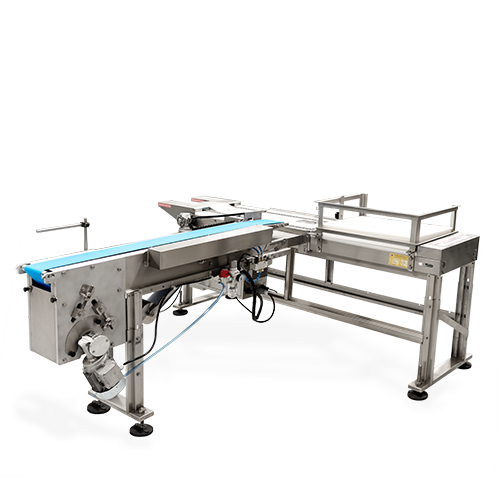

Suitable for many types of industries such as labs, farming, and pet foods to name a few.

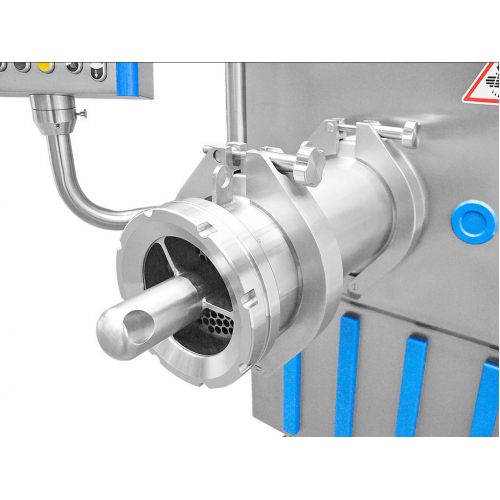

It grinds the animal bone into small fine paste with Unger type cutting system, kidney plate, two more plates such as 10mm with two double cut blade knifes.

Ability to crush and mince all types of bones, easily grinds whole chicken carcass. This equipment saves you time and money and does the job of two machines.

Suitable for these types:

|  |

| Specifications: | Applications and Food industries: |

|---|---|

|

|