2D Industrial Meat Dicer and Slicer

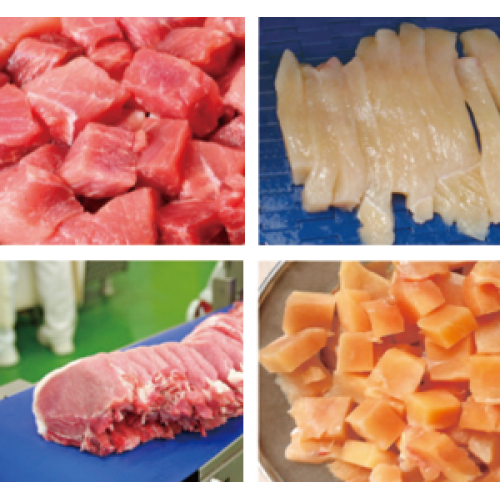

The 2D dicer /slicer is a two-dimensional dicer. It can strip, cube or dice beef, chicken, pork, lamb, seafood, cheese, cooked meat, or other products with a temperature less than -2℃.

It can be connected with a horizontal slicer to achieve a size control of 3D products.The length and width can be cut, the thickness cannot be changed or adjusted with this machine

Features:

- High production capacity, precise cutting, and no need to use two sets of machines to achieve cube cutting.

- Tough and fatty products with sinew or gristle and vegetables also can be cut.

- Finished product has a clean cut with no connective pieces, no loss of structure, and no moisture loss.

- Whole machine is stainless steel made, which can meet FDA standard.

Technical Data:

- Spiral Blade- Cutting strip length: From 5mm and up (This is dependent on speed of belt)

- Circular blade- cutting cubes width: From 10mm and up

- Product temperature: ≥-2℃

- Belt width: 280mm

- Belt Speed: 3~15m/min adjustable

- Input height: 1000±50mm

- Output height: 1000±50mm

- Power: 3.86KW

- Overall dimension: 2400×1260×1700mm

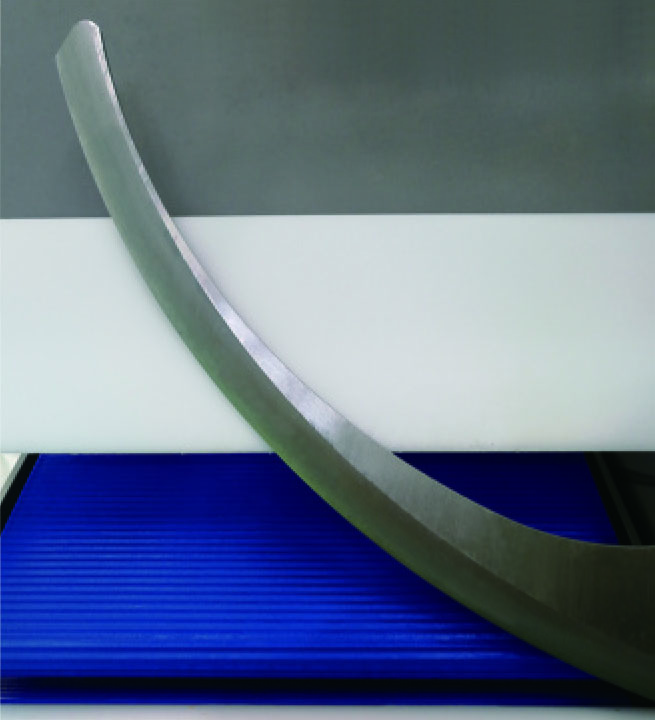

The first blade ,cut the product length.The cutting length can be adjusted by the touch screen

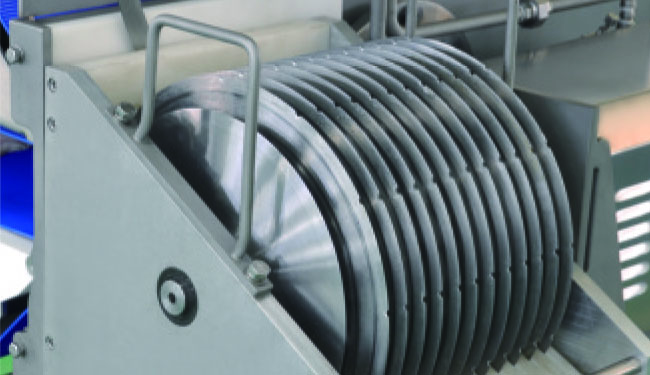

The second round blade ,cutting data is fixed ,need to make a new set of round blades to cut different data

Note: The Machine comes with one set of both circular and round blades.

Parts from well-known International Suppliers